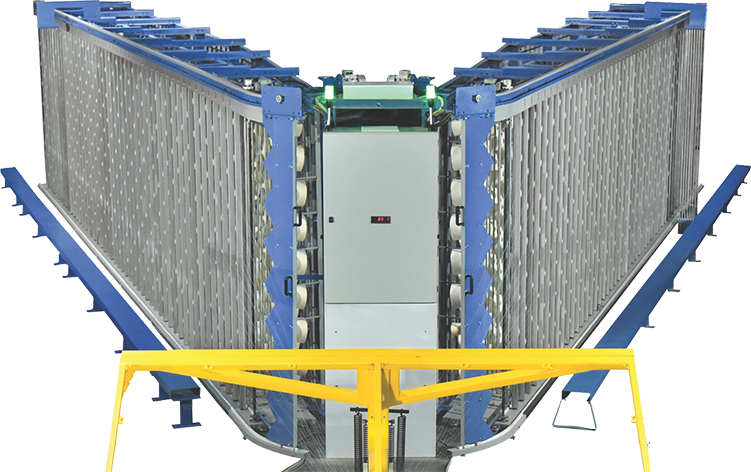

Creels

A creel machine is a textile apparatus designed to hold and feed yarns or threads to be woven or knitted into fabric. It ensures a consistent and controlled supply of yarns, facilitating smooth operation in textile manufacturing processes.

- Frame: The frame provides the structural support for the creel machine. It is usually made of metal and is designed to hold the various components securely in place.

- Yarn Guides: Yarn guides are positioned along the frame and help direct the yarns or threads from the creel to the weaving or knitting machinery. They ensure proper alignment and tension of the yarns during the feeding process.

- Yarn Tensioning Devices: These devices are used to control the tension of the yarn as it is fed into the weaving or knitting machinery. Proper tensioning is crucial for producing high-quality fabric.

- Yarn Spools or Bobbins: Yarn spools or bobbins hold the individual strands of yarn or thread. They are mounted on the creel machine and are typically arranged in rows or columns for easy access.

- Creel Bars or Pegs: Creel bars or pegs are used to support the yarn spools or bobbins on the creel machine. They can be adjusted to accommodate different types of yarns and thread sizes.

- Yarn Stop Motion Sensors: These sensors are installed on the creel machine to detect any breaks or interruptions in the yarn supply. When a break is detected, the sensors trigger an alarm or stop the machinery to prevent defects in the fabric.

- Trolley System (Optional): In some creel machines, a trolley system is used to move the entire creel assembly along the length of the weaving or knitting machinery. This allows for greater flexibility in positioning the yarn supply.

- Control Panel: Modern creel machines often feature a control panel where operators can monitor and adjust settings such as yarn tension, speed, and yarn stop motion sensitivity.